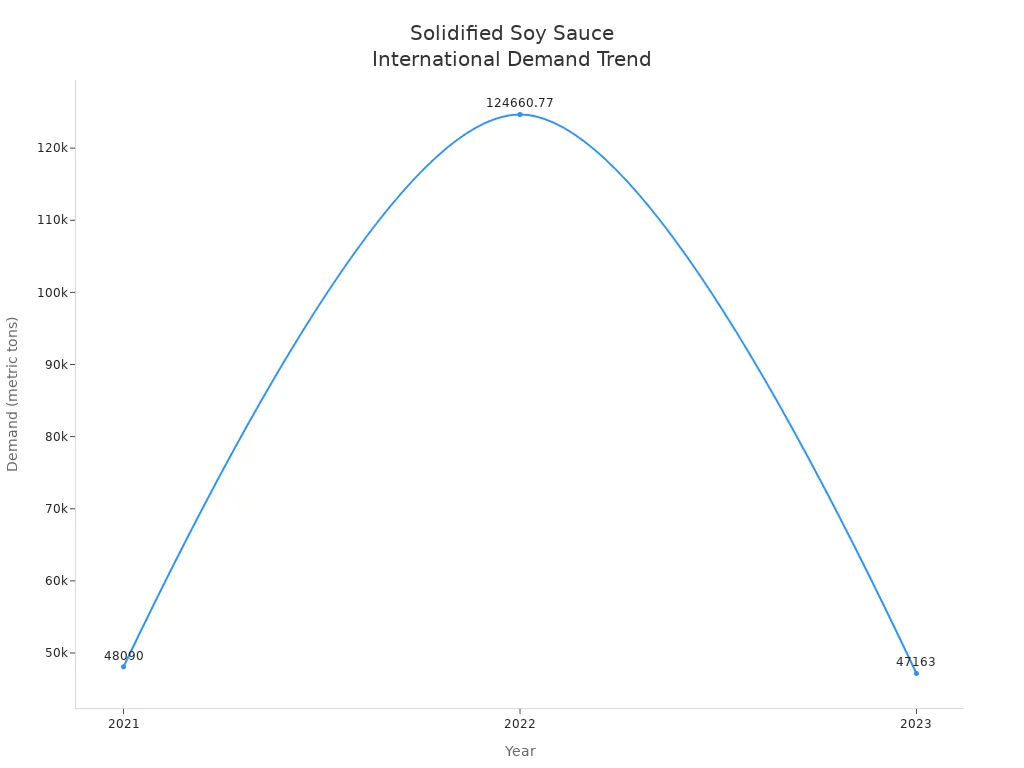

You see solidified soy sauce made in a factory with new technology. These factories use smart steps to turn soybeans and wheat into an easy-to-use product. You can see ingredient preparation, fermentation or hydrolysis, solidification, drying, and packaging as important steps. A solidified soy sauce factory gives your food special taste and keeps it safe. In the last ten years, a solidified soy sauce factory changed to meet more demand from other countries, even though people in Japan use less.

A solidified soy sauce factory is important in making soy sauce today and keeps changing the food industry.

Solidified soy sauce starts as a liquid. It changes into a solid using special steps. This makes it simple to store and use.

Good soybeans, wheat, and salt are needed for strong taste. Always pick fresh and clean items for the best soy sauce.

Modern factories use old fermentation and new machines together. This helps make soy sauce fast. It also keeps it safe and tasty every time.

Solidified soy sauce can be used in many foods. It makes soups and snacks taste better. It is great for travel because it does not spill.

Storing it right is very important. Keep solidified soy sauce in a cool, dry spot. Make sure the container is closed tight to keep the flavor.

You might ask what solidified soy sauce is. It starts as a liquid and turns solid by using special steps. Factories use machines to take out water but keep the strong taste. This makes it easy to store and use. Solidified soy sauce keeps its rich flavor. It comes as a powder or block. You can learn more about Solidified Soy Sauce and see how it helps you cook.

A solidified soy sauce factory uses new technology to make this product. Workers and machines work together to make safe and tasty seasoning. These factories are important in the food business. They help restaurants and food companies get the same taste every time.

You can use solidified soy sauce in many foods. Chefs add it to soups, sauces, and snacks. You can sprinkle it on popcorn or mix it into noodles. It works well in dry mixes and ready meals. You do not need to worry about spills.

Solidified soy sauce factories make many products. You can find different soy sauces and seasonings in these places. Here is a table that shows some common products:

|

Product Category |

Products |

|---|---|

|

Concentrated Industrial Style |

|

|

Regular Soy Sauce |

Dark Soy Sauce, Light Soy Sauce, Low Sodium Soy Sauce, Organic Soy Sauce, Seasoned Soy Sauce, Gluten Free Low Salt Soy Sauce |

|

Seasoning |

Sugar, Vinegar, Sauce Paste, Cooking Wine, Monosodium Glutamate, Sesame Oil, Vermicelli & Noodles, Fermented Foods & Canned Food, Chicken Powder, Chilli Oil |

|

New Products |

Solidified Soy Sauce, Soy Sauce Powder, Concentrated Soy Sauce |

Tip: Solidified soy sauce is good for travel or outdoor cooking. It is light and does not spill.

You can see that a solidified soy sauce factory gives you many choices. You get products for home or restaurant cooking.

You start with the right ingredients when you want to make high-quality solidified soy sauce. The main ingredients include soybeans, wheat, and salt. Each one plays a special role in the final taste and texture. You can see their roles in the table below:

|

Raw Material |

Role in Soy Sauce Production |

|---|---|

|

Soybeans |

Provide proteins for flavor |

|

Wheat |

Contributes to fragrance |

|

Salt |

Controls fermentation and prevents spoilage |

Soybeans give you the proteins that break down during fermentation. Wheat adds a natural sweetness and a rich aroma. Salt does more than add taste. It creates a brine that helps good bacteria grow and keeps harmful bacteria away. Water also matters because you use it to soak soybeans and mix the brine. The quality of these ingredients shapes the final flavor. If you use fresh soybeans and clean wheat, you get a richer, deeper taste. Salt and water must be pure to avoid unwanted flavors.

Tip: Always choose high-quality ingredients for the best results in solidified soy sauce.

You need to prepare the ingredients before you start fermentation. First, you steam or roast the soybeans and wheat. This step makes them soft and ready for the next stage. Then, you mix the cooked soybeans and roasted wheat in the right amounts. You cool the mixture to about 86°F (30°C). Now, you add koji spores. Koji is a special mold that helps break down starches and proteins. You spread the koji evenly and let it grow in shallow layers. You keep the temperature between 28–36°C and the humidity high for three days. Koji changes the mixture and gives solidified soy sauce its unique flavor.

Brine is also important in pre-processing. You mix salt and water to make a brine with 17–24% salt. This brine creates the perfect environment for fermentation. It helps good microorganisms grow and stops harmful ones. Koji works best in this salty setting, making sure your solidified soy sauce develops the right taste and stays safe.

You may wonder how soy sauce is made today. Factories use old ways and new machines together. First, workers get soybeans and wheat ready. They clean them well. Next, they steam or roast the beans and wheat. Then, they add koji mold or use acid hydrolysis. After that, they mix everything with brine. This starts the aging step. Workers take out soy sauce from the mix. They turn the liquid into powder or blocks. The last steps are drying and packaging.

Clean soybeans and wheat.

Steam or roast them.

Add koji mold or use acid hydrolysis.

Mix with brine to age.

Take out soy sauce.

Make it solid.

Dry and pack it.

Machines help keep things clean and fast. You get soy sauce that tastes the same each time. Technology helps control heat, wetness, and timing. This keeps the flavor strong and safe.

Factories use two main ways to make soy sauce. One way is fermentation. The other is acid hydrolysis. Fermentation uses time and koji mold to make deep flavor. You mix soybeans, wheat, and salt. Koji mold grows in the mix. The mix sits for months or even a year. Enzymes break down proteins and starches. This makes umami flavor and a nice smell.

Acid hydrolysis is much faster. You boil soy meal with hydrochloric acid. Then, you add sodium hydroxide to make it safe. You filter and clean the liquid. Factories add salt, caramel, and corn syrup. This makes the taste and color better. This way skips fermentation. The flavor is not as rich. It only takes days to finish.

|

Aspect |

Fermentation Method |

Acid Hydrolysis Method |

|---|---|---|

|

Production Process |

Takes months or a year |

Takes only days |

|

Flavor and Aroma |

Deep umami, nice smell |

Salty, not much smell, may use flavor boosters |

|

Safety |

Safe, no bad leftovers |

May have bad leftovers like 3-MCPD |

|

Cost |

Costs more, takes longer |

Cheaper, faster |

Fermentation gives better taste and is safer. Acid hydrolysis is quick but not as tasty. Factories pick the method based on what they need.

Note: Natural fermented soy sauce uses only soybeans. No chemicals are added. This gives a complex taste. Chemical soy sauce uses acid hydrolysis. It is faster but may have unwanted stuff.

After aging and taking out soy sauce, you make it solid. Machines remove water from the liquid. This keeps the taste strong. It also makes soy sauce easy to store. Factories use spray drying or freeze drying. These turn the liquid into powder or blocks. The flavor stays locked in and safe.

Workers control heat and wetness during drying. This keeps the taste fresh and stops spoilage. Solidified soy sauce keeps its flavor for a long time. You can use it in many foods. You do not need to worry about spills.

When drying is done, workers pack the soy sauce. They use sealed bags or airtight containers. This keeps out water and air. It protects the taste and keeps the product safe.

Good storage is important for safety and taste. You should:

Keep soy sauce in a cool, dry place.

Close the container tight after using.

Keep away from heat and light.

Check for mold if stored in warm, wet places.

If you do these things, the flavor stays strong. The product stays safe to eat. Even though solidified soy sauce has lots of salt, it can spoil if not stored well.

Tip: Always close the container tight. Store it away from heat and light. This helps keep the best flavor.

Now you know how soy sauce is made in factories. The process uses old ways and new machines. You get tasty, safe, and easy-to-use soy sauce.

When you taste solidified soy sauce, you notice a special flavor. This flavor comes from a careful process in the factory. Workers use new methods to keep the taste strong and even. You can taste umami right away. Special acids and aroma compounds help make this happen.

Organic acids like citric acid give a sour taste.

Succinic acid makes the umami stronger and the saltiness smoother.

There are over 170 flavor compounds in good soy sauce. These include alcohols, esters, and aldehydes. Some, like ethyl butyrate, make it taste fruity. You also get umami from 15 main aroma compounds. All these work together to make a rich and deep taste.

Tip: The umami in solidified soy sauce makes your food taste better and more filling.

You want your soy sauce to be safe and taste the same every time. Modern factories use strict rules to make sure of this. Workers follow hygiene rules and wear special uniforms. They go through air showers before working. Machines do most of the bottling to keep things clean. Workers check and write down results often.

|

Measure Type |

Description |

|---|---|

|

Certifications |

Factories have FSSC 22000, ISO 9001, and HACCP for safety and quality. |

|

Hygiene Controls |

Workers wash hands, wear uniforms, and use air showers. |

|

Automated Processes |

Machines bottle and pack soy sauce to keep it clean. |

|

Regular Inspections |

Staff check machines and hygiene rules often. |

|

Inspection Records |

Factories keep records for every check. |

Factories also follow world safety rules. They test for bad bacteria like Salmonella and Listeria. They check for colony count and coliforms to keep the product safe. Clean steps at every stage stop germs from getting in.

You can trust that solidified soy sauce from a modern factory gives you both umami and safety in every bite.

There are big differences between old and new ways to make soy sauce. In traditional brewing, you use natural fermentation. You mix soybeans, wheat, and salt. The mixture sits for months. This slow process makes strong umami flavors and a rich smell. No chemicals are added. The process is never rushed.

Modern factories make soy sauce much faster. They use chemical additives like hydrochloric acid or sodium benzoate. These speed up production. Traditional fermentation gives stronger umami flavors. Modern ways make lighter sauces with less flavor.

Modern brewing uses machines and chemical hydrolysis. You can finish in just days. Acids break down proteins quickly. This method makes a lighter taste. The flavor is not as deep. You get more soy sauce in less time.

Traditional soy sauce uses natural fermentation. Modern methods are faster and cheaper. Chemical hydrolysis makes soy sauce in days. This way does not give the same deep flavor as traditional brewing.

In Japan, most soy sauces use the honjozo method. This means natural fermentation is important. In China, many factories use short brewing times and chemical methods.

In Japan, about 80% of soy sauces use the 'honjozo' method. Natural fermentation is key. In China, only about 40% are naturally brewed. Many use shorter fermentation.

Modern brewing has many good points. Machines control temperature and humidity. You can make soy sauce faster and safer. Automation helps keep each batch the same. You save money and make fewer mistakes.

New technology in fermentation and automation is important. These help make soy sauce taste the same every time. They also lower costs and make work easier. Factories follow strict safety rules. This keeps the product safe and builds trust.

You now see more types of soy sauce because of new brewing methods. Factories make products for people who care about health and clean labels.

|

Product Type |

Description |

|---|---|

|

Soy-based sauces |

These have umami flavor. Health-conscious people like them. |

|

Zero Added Soy Sauce |

These have no extra additives. They are simple and clear for consumers. |

More people want soy sauce with no preservatives or fake ingredients.

Makers change recipes to fit health and diet needs.

The soy sauce market grows with new ideas. Factories respect old traditions but also make new flavors.

You can pick traditional brewing for deep flavor. Or choose modern brewing for speed and more choices. Modern factories make soy sauce safer, faster, and more flexible.

You can see that solidified soy sauce factories use new machines. These machines help make good products fast and safe. Modern technology controls how the soy sauce ferments and dries. This keeps the taste strong and the product safe to eat. These new ideas help the food business grow. You get more choices for cooking at home or eating out.

|

Innovation Type |

Consumer Benefit |

Culinary Use |

|---|---|---|

|

Probiotics |

Helps your stomach stay healthy |

Makes many foods taste better |

|

Low-sodium options |

Better for your health, still tasty |

Good for healthy meals |

|

Gluten-free |

Safe for people who can't eat gluten |

Used in lots of different foods |

You can also try things like soy sauce powder or concentrated soy sauce. These give you fun new ways to cook.

Hi! Click one of our members below to chat on