How We Develop Our Sauces

|

Functions We conduct careful research on determining how the market can best use our condiments. Industry experts review check the need in major markets and develop appropriate sauces and seasonings to fill the gap. |

|

|

Diversity As we continue to innovate our product lines, we develop diverse sauce types that cater to different cuisines and adapt to popular dishes worldwide. We also make sauces to match the changing dietary preferences consumers have. |

|

Technology With the progress of food manufacturing technology, we utilize modern tools to improve the quality and flavors of our sauces. Biological enzymatic hydrolysis, membrane and extraction technology, and immobilized yeast technology are some of the technologies we use to make better products. |

|

Elevating the Level of Chinese Condiments

PRB moves to update our product formulations, packaging, and specifications according to the changing needs of the global market. We also develop and enrich our product lines in response to the market demand.

|

|

|

| Formulation | Packaging | Specification |

| We modify existing formulations based on the current market demands, laws, and regulations. | The packaging’s design and language are adjusted to match the client’s target audience. | Product specifications are displayed on the packaging per the needs of the market. |

|

Encouraging Healthy Eating We’ve developed a range of products that support consumers’ pursuit of healthy eating. |

|

|

|

| Organic Soy Sauce | Gluten Free Low Salt Soy Sauce | Steamed Fish Soy Sauce |

|

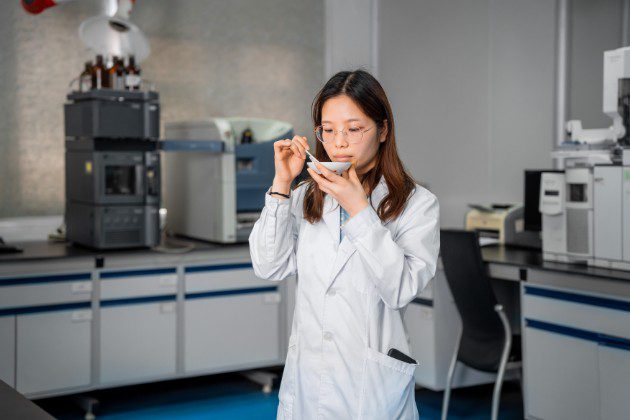

Meticulous Taste Research To guarantee the optimal taste of our sauces, we employ a specialized sensory evaluation team from seasoned industry experts.

They evaluate samples of every batch and check if there are sensory differences and make sure formulation is consistent per product. Only those that pass the sensory evaluation are released for shipping. |

|

Hi! Click one of our members below to chat on